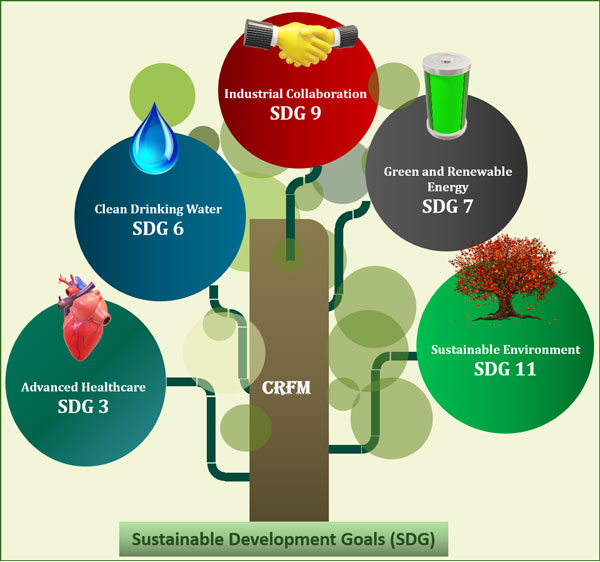

CENTRE FOR RESEARCH IN FUNCTIONAL MATERIALS (CRFM)

Contact Us First floor, Fire Lab Building, JAIN (Deemed-to-be University)JAIN Global Campus, Jakkasandra Post, Kanakapura Tq Ramanagara District-562 112, Karnataka, India +91 9449293499 info.crfm@jainuniversity.ac.in

We investigate and develop electroactive materials, systems, and architecture for the energy and water nexus. They are essential for electrochemical energy storage, harvest, and effortless seawater desalination. We use various synthesis methods (chemical, thermal, and physical) to synthesize efficient electroactive materials, including organic-inorganic composites, metal-organic frameworks (MOFs) and polymers, nanocarbon and inorganic materials. Synthesis is pursued in energy storage systems such as batteries, supercapacitors, and hybrid devices to increase energy and power density and expand cyclability. Similarly, we produce electro catalysts for photo/electrochemical water splitting and electro catalytic oxidation of ammonia borane, hydrazine, and alcohols to get efficient, inexpensive, earth-abundant, and environmentally friendly materials. Our systems and architecture development focus on the desalination of saline water using hybrid fuel cell-type electrochemical desalination, capacitive, and Faradaic deionization. Furthermore, the fabrication of microfluidic electrochemical devices of different architectures for sensing, capturing, and detecting cells and drug impurities.

Due to their exceptional chemical and physical properties, highly porous materials, such as metal-organic frameworks (MOFs), covalent organic frameworks (COFs), hierarchical zeolites, mesoporous silica, porous organic polymers (POPs), and carbon-based materials offer immense potential across various sectors. These advanced materials offer tunable porosity, high thermal and chemical stability, and enhanced selectivity, making them ideal for applications in adsorption, separation, sensing, and renewable energy storage. However, their practical applications are often limited by their intrinsic fragility and powdered crystalline forms. To overcome these challenges, efforts are being made to enhance their macroscopic shapability, enabling easy-to-handle structures suitable for real-time industrial use.

This research focuses on developing engineered porous materials to expand their applicability in diverse fields, including water treatment, gas separation, energy storage, and catalysis. By designing advanced materials such as aerogels/hydrogels, carbon-derived frameworks, hydrophobic porous materials, and magnetic composites, these innovations aim to address critical challenges in environmental remediation, resource recovery, and sustainable energy solutions.

Lab-on-chip (LOC) devices have emerged as powerful tools for biomedical research, diagnostics, and therapeutic monitoring. These miniaturized systems integrate microfluidic technology to manipulate microenvironments and microscale particles, enabling precise and efficient biological analyses. One key application of LOC technology is in liquid biopsy, where cellular entities such as circulating biomarkers can be isolated in a minimally invasive manner, providing critical insights into disease progression and treatment response. Microfluidic-based separation techniques in LOC devices can be broadly classified into physical and immunological methods. Physical techniques leverage intrinsic properties such as size, density, and deformability, while immunological approaches utilize surface markers, receptors, and bio molecular interactions for targeted capture. By combining these strategies, LOC platforms enhance the sensitivity and specificity of biological sample analysis. Beyond disease diagnostics, LOC devices are being developed for applications in personalized medicine, drug discovery, point-of-care testing, and environmental monitoring. Their ability to miniaturize and automate complex laboratory procedures holds immense potential for transforming healthcare and research with faster, cost-effective, and more reliable solutions.

This research aims to design innovative 'easy-to-use' and 'cost-effective’ analytical devices for detecting toxic ions such as mercury, lead, arsenic, and fluoride in drinkable water with the naked eye. Organic receptors, natural pigments, and functionalized nanoparticles are used as molecular sensors to detect these ions quickly. These sensors with remarkable sensitivity/selectivity are rigorously tested in the laboratory. Various analytical approaches for molecular confirmation are used to characterize the synthesized sensors. Further, for the fabrication of devices, these sensors are loaded onto substrates through the functionalization of paper pads for on-site detection and also through the functionalization of cellulose fibres for swab kit manufacture. The gadgets would be ideal for in-home sensors in urban and rural homes for monitoring the presence of hazardous ions in drinking water.

Chemical Vapor Deposition (CVD) is an advanced technique for fabricating high-performance materials with precise control over morphology, composition, and functional properties. By utilizing high-temperature environments under controlled conditions. CVD enables the controlled synthesis of nanostructured carbon materials, including carbon nanotubes, graphene, and carbon nanofibers, with tailored properties for energy storage and catalysis. This method plays a crucial role in developing advanced coatings, nanomaterials, and porous frameworks for a wide range of applications. CVD also facilitates the deposition of various metals, semiconductors, and hybrid materials, enhancing their physicochemical properties for use in fields such as environmental remediation, catalysis, energy storage, and biomedical applications. Diverse precursor sources, including waste-derived materials, can be transformed into high-performance functional materials. With its ability to engineer materials at the nanoscale, CVD continues to be a key technology in advancing sustainable solutions for pollutant removal, targeted drug delivery, membrane technologies, and next-generation electronic devices.

A hydrogen economy is a promising future energy system using hydrogen as the primary energy source. Hydrogen is a clean and abundant energy carrier that can generate electricity, power vehicles, and heat homes and businesses. While still in its early stages, the hydrogen economy is gaining traction as a means to reduce greenhouse gas emissions and combat climate change. However, several challenges must be addressed before its full realization. One major challenge is the cost of producing hydrogen. Hydrogen can be derived from various sources, including water, fossil fuels, and biomass, but production costs remain relatively high. CRFM is actively engaged in hydrogen production via water splitting, utilizing earth-abundant materials such as transition metal oxides, hydroxides, chalcogenides, phosphides, redox-active macrocycles, and MOFs as electro catalysts for water electrolysis. These materials offer a cost-effective and efficient approach to hydrogen generation. We are also exploring novel strategies to enhance their performance, aiming for more sustainable hydrogen production that minimizes environmental impact.

In addition to production, hydrogen storage is critical for its practical application. Hydrogen has a low volumetric density, making efficient storage a significant challenge. CRFM is researching advanced storage solutions, including metal hydrides, porous carbon materials, and MOFs, which offer high storage capacity and stability. These materials can store hydrogen safely and release it efficiently when needed, ensuring a reliable supply for various applications. Furthermore, hydrogen sensing plays a vital role in ensuring safety, as hydrogen is highly flammable and leaks must be detected promptly. We also develop sensitive and selective hydrogen sensors based on nanomaterials, metal oxides, and conducting polymers. These sensors provide rapid and accurate detection, enhancing safety in hydrogen production, storage, and transportation. By addressing hydrogen production, storage, and sensing challenges, CRFM aims to contribute to a cleaner and more sustainable energy future.