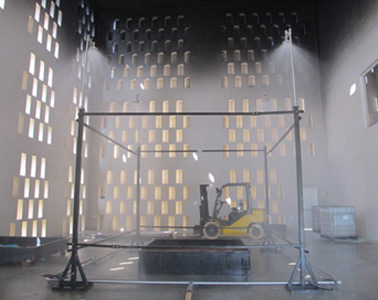

It has a unique porous wall feature developed indigenously through computational studies with an aim to provide natural and proper ventilation while preventing ambient air disturbances. This system has helped in replacing expensive mechanical ventilation commonly adapted in fire labs. Indoor test facility certification and fire fighter training will be carried out by experts in the area.

| Year | No. of Companies | Fire Tests | Environmental Tests | Major Names |

|---|---|---|---|---|

| 2015-16 | 12 | 22 | 0 | UAE: NAFFCO, JC Cooling LLC, AL-ANDALOSIA, AL-MULLA, Empower Technologies, Fire Terminator Singapore: Eon Chemicals Egypt: International Security Safer Co India: Maharashtra: Super fire Engineering, BPCL, HPCL , KV Fire Chemicals, Cryptzo Engg. Pvt. Ltd Karnataka: HPCL, Tyco products, Telangana: ONGC Tamilnadu: MRPL, CPCL, Uttarakhand: Foam Tech Antifire, Haryana: BPCL Gujarat: Kanadia, Vimal Fire Controls |

| 2016-17 | 16 | 28 | 0 | |

| 2017-18 | 26 | 24 | 645 | |

| 2018-19 | 32 | 23 | 303 | |

| 2019-20 | 18 | 26 | 690 | |

| 2020-21 | 22 | 62 | 392 | |

| 2021-22 | 32 | 58 | 555 | |

| 2022- 23 | 12 | 88 | 662 | |

| 2024-25 | 34 | 45 | 716 | |

| 2025-26 Q1 | 18 | 11 | 147 | |

| 2025-26 Q2 | 12 | 24 | 168 | |

| 2025-26 Q3 | 12 | 10 | 136 |

Analytical equipment like FTIR equipment for analysis of foam and other chemical samples, DCP particle size analyzers, Tensiometer for foam spreading coefficient measurement and thermal imaging cameras have been installed in the first phase. The Center has 12 bar compressed air utility and industrial gases like N2 at about 20 required locations. LAN facility with WiFi provision has also been installed in order to facilitate communications.

The administrative block is built on an area of 20,000 sq ft area and encompasses 2 audio visual class rooms of 40 seat capacity, faculty chambers, discussion room and a library. Additionally, a large pool fire facility upto 4 m x 4m with provision for 120 channels TC data logging and wind monitoring provision has also been developed. The facility has UPS power and an independent control room.

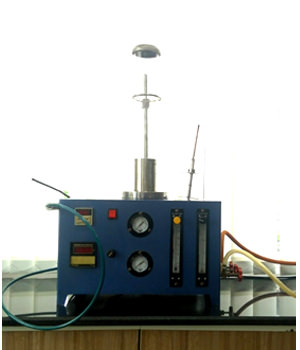

Several equipments are necessary for testing fire safety related products like fire retardant clothes and construction materials are being procured. Typical equipments available at the center are mentioned below.

Extensive work has been carried out in the center in the areas of biomass combustion. 3 patents have been filed and technology is transferred to stove manufacturing industries. Typical equipments related to this are shown below;

A solar pump test facility is established UL India pvt ltd at FCRC premises. The facility caters to testing solar pumps using simulated power supply similar to typical solar summer/winter day as prescribed by MNRE standards.

| Year | No. of Companies | No of Tests | Major Names |

|---|---|---|---|

| 2015-16 | 12 | 99 | Karnataka: MEC, Gupta Agro, Mecwin, Mercury Electronic, Shakti Pump New Delhi: CEL Maharashtra: Duke Pumps, Ecozen Solution Pvt Ltd West Bengal: Shankar Machinery Chhattisgarh: Swasthik Solar, Kalwant Goyal, Rawmate solution, Kamala Instruments Madhyapradesh: Kirloskar pumps Uttar Pradesh: Shakthi Pumps Telegana: Suguna Motors, Access Solar, Novus Green Energy Systems Gujarat: Rotomag Motors & Controls, Duke Plasto Techniques |

| 2016-17 | 15 | 280 | |

| 2017-18 | 18 | 330 | |

| 2018-19 | 22 | 508 | |

| 2019-20 | 19 | 532 | |

| 2020-21 | 26 | 335 | |

| 2021-22 | 23 | 195 | |

| 2022-23 | 26 | 113 | |

| 2023-24 | 3 | 37 | |

| 2024-25 Q1 | 1 | 8 |